Merlin XX restoration

This will follow the restoration of a Merlin MK XX to

static running condition. We hope to give our customers and visitors an insight

into the challenge and rewards of such a project. The information is kindly

being supplied by Dave who is the owner of this beautiful Mk XX and he gets our

grateful thanks for sparing the time to share his project with us.

Updates will be listed in

"What's New"

Updated 17/11/09

Welcome to this page which Graham has kindly put together

for anyone interested in following my restoration of this Merlin XX engine. I

bought the engine just before Christmas 2007. There are a number of people, all

of whom have played a big part in enabling me to do this, and if any of you read

this (you know who you are!), I would like to say a huge thank you.

I have tried to trace as much history as possible about the engine in the short

time I have had it. The only definite information so far has come from the Rolls

Royce Heritage Trust who have been very helpful with information and advice. The

engine was one of 2000 built at the Rolls Royce factory in Glasgow to contract

number SB4601/40 between 9th January 1942 and 1st June 1942. This particular

engine 52771, was built in the week ending 23rd Jan 1942 and was despatched on

7th Feb 1942. Beyond that the only additional information was 'believed written

off in Russia' and that it was probably installed in a Hurricane II. Certainly

the Hurricane link is likely as the engine has upper coolant galleries for a

header tank mounted behind the engine, and a chain sprocket for manual starting,

both features that I think were unique to the Hurricane installation. Beyond

this, most of the information is very uncertain, but it does seem likely that it

was recovered from Russia at some stage, and there are conflicting reports

that suggest it could have been connected in some way with three different

Hurricane airframes. I would be extremely grateful if anyone has any more

information that Graham could pass on to me.

This will be a huge learning curve, but the intention is to try and restore this

engine to running condition. Clearly this will depend largely on what we find

once it starts coming apart, but one thing is for sure, this will be a long term

project, not least of all because I need to move house before making a start!

So, it could be a while before it gets under way, but hopefully the photos will

be worth the wait.

Enjoy Dave

The Merlin XX

ran on 100 octane fuel. This allowed it to be run at higher

manifold pressures, which were achieved by increasing the "boost" from the

centrifugal type supercharger. The result was that the otherwise similar engine

delivered 1,300 hp (970 kW). Another improvement made to the XX and future

Merlin variants was a redesign of the cooling system to work using a 70/30%

water/glycol mix rather than the 100% glycol of the Merlin I, II and III series.

This allowed the engines to run some 70 degrees C cooler, substantially

improving engine life and reliability. This also removed a potential fire hazard

from Merlin powered aircraft, as pure ethylene-glycol is a flammable liquid.

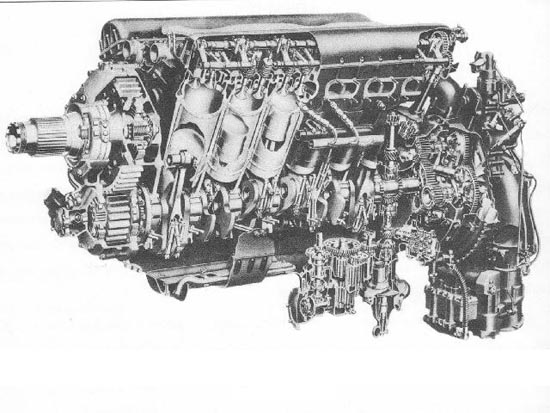

The Merlin XX

cutaway

Updated 11th December 2008

Well, it's a start! The engine is still quite inaccessible

at the moment, but I did manage to take off one cam cover.

It appears to be quite good inside (so far!).

The cam, rockers and bearing brackets etc are all well

preserved. The only items of concern at this stage are the valve springs as they

are heavily pitted with corrosion, so I would certainly not be happy to use them

if all goes well and it is still built to run.

Hopefully the engine will be moved to a clear area soon,

so then I will be able to really see how well the rest of the engine has

survived.

The aim is to break the engine down into main sections,

cylinder blocks, reduction gear, carb and supercharger etc.

There is a crack in the main crankcase casting by one of

the rear engine mountings so I want to get the crankcase fully stripped so that

it can be repaired.

Then, starting with the overhauled crankcase, hopefully it

will be a case of restoring each item as it is needed to put the engine back

together. Makes it sound easy!!!

Updated 17/11/09

At last, there's been some more progress with the Merlin.

While I was waiting to move the engine to a bigger space, I got stuck in to

overhauling the ignition harnesses. This proved to be a much more intensive job

than I expected, largely due to the fact that so much of the original exhaust

harness was damaged or missing. I'm very grateful to all those who helped to

provide all the bits and pieces that I needed to complete the task. The picture

shows the completed exhaust harness, and the inlet one is now finished too.

I began the strip down of the engine by removing the V-drive and reduction gear.

As I broke the seal between the reduction gear case and crankcase, a

considerable quantity of water drained out. I suddenly had images in my mind of

the pinion being a pile of rust at the bottom of the casing! Thankfully it

proved not to be the case at all. As can be seen in the picture, the condition

appears to be remarkably good given the length of time that the engine has been

sitting idle (about 65 years!).

Since then I have removed the camshaft assemblies, carb and supercharger, and

most of the 'bits and pieces', like pipe work, exhaust stubs, coolant galleries,

magnetos, fuel pump and generator bracket. The engine is looking quite bare now,

and much smaller (relatively speaking!). The next step will be to remove the

wheelcase. At that stage it is time to lift the one-piece blocks off, and

finally see if the cylinder bores have survived.

It is remarkable that given the several hundred nuts, bolts and lock rings that

have so far been undone, not a single fastener has been seized or failed to

undo, even though most nuts were corroded beyond recognition. A fraction of a

turn with small vice-grips and they all wound off by hand. So far, I have about

2,500 new nuts and washers ready for the reassembly. This only covers the

bolting together of the main components! Thank goodness for e-Bay and the

internet.

|