The Spitfire Spares Mk VIII Spitfire

Welcome to the Spitfire Spares Full

scale replica page

Available

Very Soon

Climb

into

the

Cockpit

and Taxi

a MK

VIII

SPITFIRE

This is the story of the Spitfire Spares Spitfire.

UPDATED 21/08/07

Finally we have

fitted to engine 04/02/07

Progress ought to be a bit more rapid

now, famous last word's.

More Picture's added 5th march

2007 Fitting the exhaust stub's.

We have sorted the oil tank you can see it in the

pictures behind the fire wall in front of the instrument panel. We also have a

fuel tank, I bought it a couple of years ago with this job in mind and it fits

like a glove. I am mounting it behind the firewall above the oil tank. It has

two fuel outlets, perfect, and is also the right depth. The best thing of all it

has a fuel sender and itís a 38 gallon tank, it's Perfect, not a clue what's

it's from but it's dated 1947. I actually have a 38 gallon smithís fuel gauge. I

havenít got the correct 37 gallon, thought 38 was near enough. Looks allot

better now we have got rid of the air intakes and cooling outlet. We are going

to get good quality hose to connect the water, oil system and fuel. The great

thing about the hydraulic prop drive is that you can turn it off. The prop will

operate from the throttle as in the real deal and can be stopped completely.

This way we can run it at shows without all the worries of chopping someone's

head off. Shouldnít cost anymore to insure than a vintage car. Hoping to show

her off at Popham this summer. Lots to do yet

The Fuel tank

Updated 10 MARCH 2007

Having discovered the Stubs were

fabricated facing down instead of up they have been put right and the

cowling offered up for fitting.

UPDATED 27/05/07

The engine to tank connections have been

completed. The flow of coolant is reversed through the carb manifold and the

rear head outlets and carb manifold flow directly back to the tank.

UPDATED 2106/07

Fuel tank rough first fitting

Note the oil tank below the fuel tank. There will

be heat proof matting on theoil tank and several layers of high impact foam.

Water tank sealed in. The fuselage will receive a

complete make over when the mechanics are done so don't worry about the rough

fit.

Fuel tank final fit a bar with padding will be

welded in behind the fuel tank to seal it in place.

Note some of the instruments have been threaded

through from the engine ready for panel fitting.

The cockpit will be completely re- done, its a

bit rough at the present. Note the high impact rubber under the fuel tank, there

is a layer of heat proof material over the oil tank although we don't expect any

heat problems with the oil due to the limited running time.

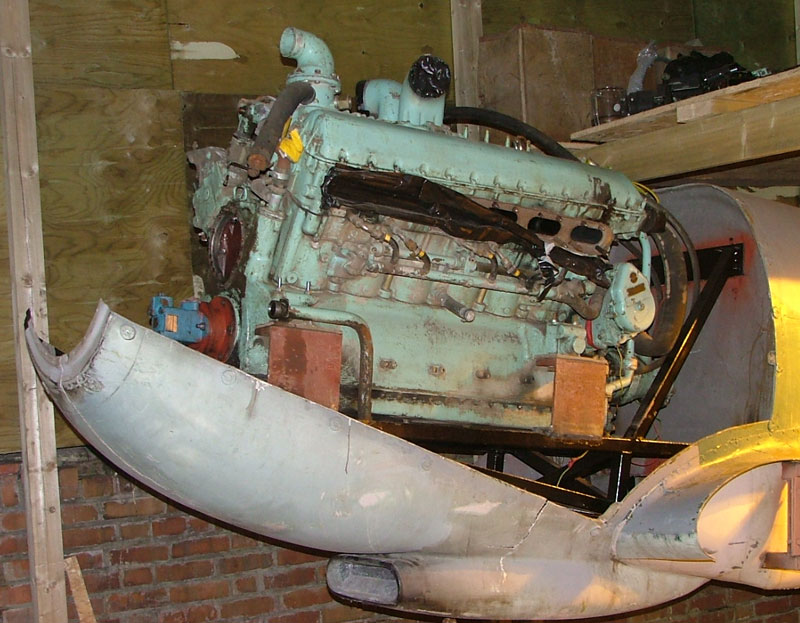

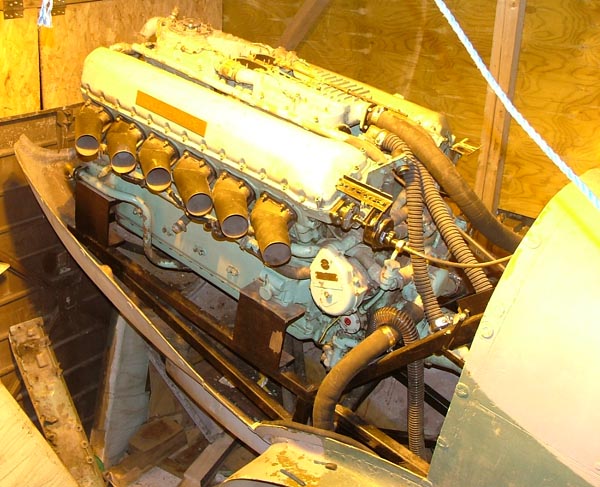

The engine with all oil and water connections in

place. The engine will be cleaned and repainted in black with some original

Merlin rockers

You can see the start of the throttle linkage at

the top of the engine mount. Its the tube on the triangular brackets.

Note the oil pressure gauge sender unit in place

below.

UPDATED 30/06/07

Fuel tank final fix, throttle in place, we had to

use a P47 Thunderbolt throttle as we don not have a genuine spitfire one at this

time. The rudder bars are in place to carry the pedals. Note the top and

underside of the fuel tank is lined with high impact foam. High impact foam to

lesson the vibration to the instrument panel fixed around the bulkhead.

Fuel tank, Oil tank, Throttle and rudder bars all

in place.

Throttle in place.

Rudder Bars, you can see the fuel lines running

out from the bottom left and right of the fuel tank.

UPDATED 05/07/07

Throttle linkage complete and

working. It may not look pretty but it works.

Here is the radiator neck finally fitted to the

carb cooling manifold, this will be connected to a header/overflow pipe

Original stick being fitted

UPDATED 10/07/07

Rudder bar and pedals in place

Rear of the rudder bars. The two holes in the

cross member will have threaded bar attached with solid bar running to the rear

wheel and rudder.

UPDATED 26/07/07

One part of My MKVIII Replica I want to keep as

original as possible is the cockpit. The rev counter was a challenge. The meteor

has an electric generator to drive the rev counter, the original Spit was of

coarse mechanical. The original rev drive ran off the cams at a 4:1 reduction,

i.e. 1/4 engine speed. So I needed a 4:1 reduction gearbox that would fit the

meteor drive for the Rev electrical generator. Tall order!!!! I have a few

generators that work the opposite way they convert mechanical drive from the

Merlin into electrical drive, out of curiosity I took one apart, what a result

they contain a 4:1 reduction gear box. Having removed the armature, I connected

the mechanical drive to the rev counter and gear box and put an electric drill

on the gear box. One problem the meteor rotates in the opposite direction

to the Merlin, that's when luck was really on side for a change, the rev counter

works quite happily regardless of which way the gear box spins. I guess they

designed them that way for different handed engines, I know this kind of rev

counter was used in loads of other RAF types with different engines. Here

is the unit connected up with the flexi drive cable attached.

UPDATED 21/07/07

Tail wheel completed and fitted to rudder bars,

it works!!! The rudder has had lots of

fabrication to fit so that it works. The rudder,

tail plane and elevators will be removable

for transport. Some of the panels have been

prepped for painting.

Instrument panel being wired the fuel gauge now

works with the fuel tank sender

Manual Rev counter drive conversion in place, top

cowling has been test fitted.

New Rudder pedals fabricated from steel the repro

alloy ones snapped and were like a

honeycombed inside.

Technical info

Graham

I have only just read this (request on BTPA page) and note the reply from

Chris (our very good friend from tractor pulling) We run the jet tractor

Satans Toy, the Meteor tractor Devils Symphony, and the Alvis Leonides,

Lucifers Child (Riot Racing, Neal

And Nigel Davis) The modded distributor you saw on Salvage squad was all my

own work, but in reality was a complete load of rubbish, yes it did work,

but the sensor head was extremely fragile, so we have progressed a mile

since then. Nick Meade who is a friend and owns the tank has worked with us

now for 3 years and we have developed the perfect electronic conversion of

Meteor mags for the tanks. The mag is converted to run on 24 volts and

externally looks identical to the original, apart from a small discreet

lever to adjust the static timing. Power is a single wire that replaces the

wire which was originally the booster coil. We have found that if you

replace the inlet mag only, the engine will start virtually instantaneously

and the exhaust mag will pick up as soon as a couple of hundred RPM is

achieved. This is extremely important as the starter motors are also rubbish

and if the engine pops back the gears will almost certainly fail. Three of

Nicks Centurions are now fitted and it is notable that he is the only person

who has the confidence to take Centurions to shows at the moment, By the way

the Meteor in the tank is governed to 2500 rpm but if your 4b has a Merlin

Crank (this is highly likely if it is a late engine) it will run well above

3500. Devils Symphony is governed out at 4000 and this is very easy to

achieve with the electric ignition, by using an Omex adjustable rev limiter

(Demon Tweeks around ?80). At Heddington show Peter Grieve had his two

Merlins which are standard and set at 3000 RPM. Peter was well impressed

with our Meteor and you couldn't tell the difference when the two were

running, they sound identical. Our Meteor uses the same electronics as the

tanks but we mount the units into V12 jag distributor bases and run them on

the end of the cams, this is purely to save weight in the Mini tractor

class, as we run ordinary N9Y sparking plugs and ordinary plug leads. Timing

is critical on these engines for performance and to stop oil smoke, so this

also helps as we do away with the automatic advance retard.

QUESTION

I ended up getting new mags from some German tractor pullers,

they also fitted new plug caps so I can run with modern plugs. I have trying

without success until now to find out what plugs to use, they only burn

alcohol and didn't know.

I fitted the mags and now have a nice bright spark when the boost is

connected. I know what you mean about the starter, I removed the hand crank

when it jammed and it seems ok now. I like the idea of replacing one mag if

it starts better , but is it expensive?, on a tight budget.

I really need some advise because I know very little about the engine, have

read a few Merlin manuals but they are not the same. Cant seem to get a

meteor manual anywhere.

The plugs are a bloody nightmare to get out of the middle banks.

I am fitting it to my Full scale replica Spitfire so it can taxi and ground

run. I have made an engine mount, have fitted a hydraulic pump to the engine

which will drive the prop through an 1196 Ft/Llbs torque hub at 864 RPM. I

have made a stainless oil tank and have bought a 96GPH Holley self

regulating fuel pump as I intend to fit the fuel tank back in the tail away

from the engine and hot bits.

Fitting a complete original instrument panel and cockpit, all the

instruments and controls wire straight into the meteor, everything's ready

to fit as soon as I get the engine in.

ANSWER

Spark plugs that

we use are N12Y Champion number or any equivalent but if you get the small

body type with the little nut size (Ford use them a lot) they are a lot

easier to remove. The compression on a Meteor is only 6 to 1 so these plugs

are better than the original and the 12 number means they have a long snout

so they don't oil foul. We run conventional copper wire leads and ngk rubber

plug caps and have no trouble at all running on 100 LL Avgas. We run 3

Carter AFB 4 barrel race carbs and use the original fuel pumps with no

problem up to 4000 rpm. They are very good and are completely standard with

all other fighting vehicles so you can get them anywhere for next to

nothing. The Holley pump will need a fuel pressure regulator and return to

tank otherwise the original carbs will flood and fill up the centre of the

V, this is good for a fire. The original carbs are very restrictive and the

mags have a spark dump device that stops the engine at 2500 rpm. The starter

motor is going to be a bit of a pain as it will inevitably be at the back

and difficult to change, they are notoriously fragile and it is the

intermediate 6 tooth gear that is the problem. The hand turner is rarely a

problem and is very useful for timing the engine or generally fiddling about

so it might be useful to repair that. We have developed a modification to

the starter to double up the intermediate gear which seems to be working on

ours. I am working on getting a manual which if successful I will let you

copy. The oil system on the Meteor is a bit weird because in the tank it had

a 60 gallon tank and the oil cooler and filter were both in the scavenge

pump circuit and mounted above the scavenge pump. We of course only use

about 3 gallons of oil and this was not enough to prime the scavenge pump so

the sump just kept filling up, Which was Smokey to say the least. We have

modded ours to wet sump and removed the scavenge pump and she runs fine now,

but subsequently found that the scavenge pump needs a certain amount of oil

above it on the outlet side to keep it full. On the tank this is achieved

because the filter is mounted on the rocker cover. By the way the oil pickup

on the high pressure side is fairly critical in it's design so don't change

this, but we noticed that there is no filtration on the inlet side at all so

we have fitted an inline oil filter in the pickup pipe, (to protect the

pump) this is from a Renault tractor and is perfect, cheap, and dead easy to

fit. (I can get the part number if you want). and also we have fitted a full

flow high pressure spin on to the pump outlet. This is a standard Chevy Drag

race filter and handles the oil brilliantly, and of course can be changed

quickly as a service item, just like a car. The bottom end of a Meteor will

last forever so long as the oil is kept clean. The original filter was

massive, mounted on the rocker cover and only filtered the oil AFTER it had

been through the engine so was pretty useless, typical army design really.

The rocker covers are interchangeable with a tiny mod so we just got a

second plain cover and instantly have the Merlin look. We have some spares

by the way because our Meteor was complete and standard when we got it.

Peter has come up with a good mod to protect the rocker gear on his Merlins

which consists of an extra pipe being added to the heads through the

blanking plug holes and a little electric oil pump that will pressurise the

oil system to the rockers before start up. They are prone to stripping the

chrome faces during start as they dry out while standing, We have had one do

this but Peter supplied a spare and believe it or not it is only about a 15

minute job to change a rocker (well if you discount the half hour to get the

cover off). Your project sounds really great and if you need any advice or

help we will be only to pleased to try and help keep these machines

operating Oil tank capacity is no problem as the bottom end keeps very cool and

you

shouldn't need a cooler, (ours has no cooling whatsoever and only 3 gallons

of oil but after a full power run of around 30 seconds and also the drive

on, drive off, you can still put your hand on the sump which is barely warm,

rocker boxes are untouchable though) but the high pressure pump is the non

self priming type so you must keep your oil tank notionally above the oil

pump or have a saver tank that keeps a small amount of oil on top of the

pump so the pump is primed at start up. The same applies to the scavenge

pump which is why the oil pipe along the side of the sump rises up as it

goes into the sump on the sump pickup bulge. When the engine stops the oil

in the pipe cannot run up over the hump and remains in the pipe and keeps

the pump primed. Mags are no problem, we can definitely sort something there

for you and the cost can be sorted whenever. Our Meteor literally starts

first piston up, every time. Instrument wiring is easy (I'm trained in air

radar).

The Holley pump must have a pressure spec or adjuster, you will need to know

what pressure it regulates at, as the standard carbs can only handle about 5

psi or they will flood. Fuel consumption seems to be subject to a lot of

bragging and common sense can lead to the correct answers. I don't know how

much fuel a Spit carried but at 2 gallons a minute it would need 180 gallons

if you include the mandatory 50% safety factor for a 30 minute sortie, now I

may be ex RAF (Bomb Disposal) but even I believe that the Spit had a greater

range than that!. From our experience the Meteor uses about a gallon a

minute at 3500 RPM under full load and when idling at 750 RPM it is very

economical. In the tank at 30MPH it used two gallons per mile at 2500 RPM

which equates to 1 gallon per minute at full load. Realistically to save

continuous topping up a 10 gallon tank would be ideal which would give you

about a quarter of an hour of messing about. (this is all based on 100LL

Avgas as purchased from Peterborough Holmes airfield at ?1 .04 p per litre.)

It is true that you should stop a Merlin by switching off the fuel as it is

supercharged and as the engine runs down the blower will pump air and fuel

through to the exhaust pipes which are hot and bingo it all gets rather

spectacular. Not so for a normally aspirated engine as when you shut down

the carbs, next to no fuel can get in, so just switch off the sparks and

everything will be fine. As your engine will, like ours be running next to

no flywheel, if I understand your drive arrangements you will find it will

stop virtually instantly at switch off. In the tank you just have a normal

ignition switch arrangement just like a car.

QUESTION

My oil tank is about 8 gallons is this enough, I wasn't

planning to use an

oil cooler as I don't expect to run at full revs for more than 20 secs tops.

Just enough to get it taxiing. Is this going to work?

Also will the pump draw the oil up from the tank OK, I have the original oil

filter but have to move it somewhere below the rocker covers, I was going to

mount it on the engine mount above the starter motor.

I would greatly appreciate some help with the mags, I need it to start

reliably as im am hoping to offer taxi runs for enthusiasts if I ever get it

all working.

Would be great if you could visit im there most Saturdays working on the

Spit.

I have senders for instruments but not sure how to wire them, I have

original spit gauges with capillaries at present , but I should have the

electrical type on the MK8.

The holley pump I bought is supposed to be a self regulating type, its a

holley red electric 12 volt, its a smart bit of kit. Do I still need a

return and regulator?

How much petrol do they burn in standard form? I know a Merlin will burn up

to two gallons a minute , I was hoping for about 1/2 gallon a minute on tick

over. For safety sake I want to keep the fuel tank down to a minimum.

Is it true you have to switch the fuel off and let the engine run out of

fuel to turn it off, rather than earthing the mags? I have been told they

can catch on fire if you dont.

Graham

I would forget the existing oil filter, fit the Chevy spin on (this is about

5 inches in diameter and is about 10 inches tall, on our Meteor I have it

mounted on the left side just above where the mag would sit, directly above

the high pressure pump so that the outlet goes straight back into the

pressure control block on the side of the engine) and the inline filter

(this is very small) in the high pressure pickup between the tank and high

pressure pump.( go to

www.powerpulling.co.uk there are numerous pictures of

Devils Symphony and you can see the filter on the front, it is orange. The

oil and fuel tanks are the two round cylinders along the chassis sides, they

are made from irrigation tube!) How far away is your oil tank and at what

level is it compared with the high pressure pump. The scavenge return to

tank is no problem you just arrange the outlet pipe, to swan neck up a bit,

before dropping away to the tank, this ensures the pump doesn't dry out, the

standard pickup looks after the rest. To mod the Magneto we only require the

base in a sound mechanical condition. The electrical side is irrelevant but

we must have a good rotor arm. We do not need the distributor cover but we

do need the drive unit, and remember that the distributors/magneto's are

different in that they rotate in opposite directions so if you want to mod

the inlet magneto (recommended) we must have an inlet one to mod (they are

not interchangeable because of the centrifugal advance retard). Fuel:- In

fact the Meteor was tuned to run on 91 octane leaded fuel, standard for post

war military petrol, This is no longer available and the military now use 94

octane low lead (not unleaded) Your Meteor will run happily on 4 star (98

octane) leaded but it will run much better on 100 octane low lead or 100LL

avgas as it is in fact closer to 110 octane equivalent with the combustion

improvers that are added to keep piston engined aircraft running at

altitude. However strong our greenies are they can't change physics and a

piston engine needs combustion accelerators in rarified air! The Merlin was

designed to run on wartime avgas which was 130 L or 130 octane leaded. The

Battle of Britain flight spitfires run on 110 LL but do not have the

performance that the warbirds had. B of B do still have special 130 leaded

for the Messchersmidt which won't even run on 110!! By the way I have flown

in City of Lincoln, I'll tell you the story someday. The other reason for

using avgas is it is 30 p a litre cheaper. Our experience is that the fuel

pumps as fitted are completely adequate and will lift the fuel over quite a

distance, they have the added advantage that you can hand prime them and

they don't need an electrical feed. we think they are great and if yours are

no good I can get you a pair of new ones although our experience is that

they are generally very reliable. They have an advantage that they pump in

synchronisation with the engine RPM whereas an electric pump is constant or

too much at idle and not enough at high RPM. The Meteor is also fitted with

a special easy start system ( ha ha ) called KY gas priming. This is like

ether injection (you will see the little injector nozzles and pipes on the

inlet manifold) but you can if you wish adapt this and use it to prime the

engine with avgas which will start it and give the pumps a chance to catch

up. This can be manual or electrically pumped. The carburettors don't seem

to dry out unless the engine hasn't been run for a long time but our

experience is that they need a lot of fuel to start them. The Meteor is a

really good and fairly simple engine and suffers from only two real problems

i.e. poor sparks and a weak starter, overcome one or both of these and they

are extremely reliable.

QUESTION

I can keep the old filter above the oil pump, although it

sounds a poor

option.

Would like to use the oil filter you suggested. Perhaps I can remove the

filters and use the oil filter case as a tank to prime the pump? I have two

mags which are knackered, the steel pins which connect to the plugs leads

are badly corroded. I have two good mags on the engine could afford £150 OK.

Do I have to run on av gas? will my standard Mk4 b run on 4 star Leaded?

Perhaps I can do away with the holley, will the fuel pumps on the engine

lift fuel? or do they have to be pressure fed?

The oil tank should be no problem but as is the

case with the scavenge pump arrange the oil lift pipe to come up above the

pump and then drop back. This will ensure that the pump is always primed.

You will have to fit the lift filter (the Renault Tractor one) in somewhere

anyway so it will probably lend itself to go in the pipe and will add a

little reservoir to the lift pump. This filter is quite small and neat. Our

Meteor has the prop drive adapter removed and an 11.5 inch alloy flywheel

with a two plate Hayes clutch on it. The flywheel action of this is

negligible, but she will happily idle at about 750 RPM. Although the engine

will idle slower than this, the oil pressure to the cam gear gets very low

so we feel that 750 RPM is better for the engine. The hydraulics will help

as a flywheel so long as both the pump and motor are two way types. Great

that you have the K gass system but don't use the K gass, just put ordinary

avgas in it. K gass was basically ether and it is a great way of destroying

your starter motor. With the ignition upgrade all you need is a little

enrichment of the mixture on cold mornings. Nick's Centurions don't need the

primer or even choke unless the temperature is below about 10 C. You should

have no problem with the Avgas as long as you tell them that it is not going

to be used in a road car. In fact you can probably register your replica

with the flying club and buy the fuel against it. Most flying clubs make a

little profit from their fuel and are only to pleased to sell it. I take

either a 40 gallon drum or half a dozen gerry cans and there has never been

a problem. Get a receipt to keep in case you come up against the ministry

(tax guys). The plugs you have got are the identical ones to what we use and

they have never been a problem but they do need cleaning every now and

again, the Meteors and Merlins are notorious for oiling up but we have found

that you can improve this by running a modern quality oil (20/50 synthetic),

but then a real Spit had it's plugs changed every sortie! Don't throw the

Holley pump away, they are sought after by tractor pullers and dragracers

but I think the original pumps will be more than adequate and a lot less

trouble

|